Analysis of Water Contaminated Engine Oil in Engine Generator Set

DOI:

https://doi.org/10.53017/uje.66Keywords:

Generator set, Oil mix water, Cylinder liner crack, PittingAbstract

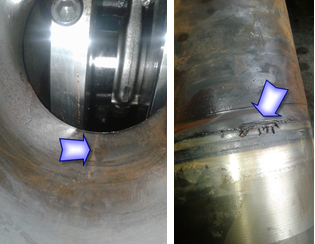

This case study was conducted in a manufacturing company that experienced a breakdown in a power generator set. A standard investigation was carried out by opening the crankcase cover and checking the dipstick. The results of the visual inspection showed that the engine oil was contaminated with water. Therefore, this study was conducted to further analyze the causes of oil contaminated with water in the unit being handled using fault tree analysis (FTA). As a result, cracks were found in the cylinder liner due to pitting on the outer liner with a pitting depth of more than 2 mm. In our analysis, pitting is formed due to the presence of air bubbles in the cooling system. Based on FTA, the formation of air bubbles is caused by the quality of the coolant. We also found that the coolant used was not added with any additives.

Downloads

References

M. Carla Estorilio, “Cost reduction of a diesel engine using the DFMA method,” Prod. Manag. Dev., vol. 4, no. 2, pp. 95–103, 2006.

K. M. Tsitsilonis and G. Theotokatos, “Engine malfunctioning conditions identification through instantaneous crankshaft torque measurement analysis,” Appl. Sci., vol. 11, no. 8, 2021, doi: 10.3390/app11083522.

A. D. Davydov, “Analysis of pitting corrosion rate,” Russ. J. Electrochem., vol. 44, no. 7, pp. 835–839, 2008, doi: 10.1134/S1023193508070100.

R. T. Mousavian, E. Hajjari, D. Ghasemi, M. K. Manesh, and K. Ranjbar, “Failure analysis of a shell and tube oil cooler,” Eng. Fail. Anal., vol. 18, no. 1, pp. 202–211, 2011, doi: 10.1016/j.engfailanal.2010.08.022.

J. Wakiru, L. Pintelon, P. Chemweno, and P. Muchiri, “Analysis of lubrication oil contamination by fuel dilution with application of cluster analysis,” XVII Int. Sci. Conf. Ind. Syst., pp. 252–257, 2017.

Wilarso, A. Domodite, H. Sholih, and Mujiarto, “Analysis of SOS Results for Engine Lubricants Contaminated by the Fuel in the 3516 TA Diesel Engine Generator Set,” J. Phys. Conf. Ser., vol. 1764, no. 1, 2021, doi: 10.1088/1742-6596/1764/1/012172.

M. Raviraju and K. R. V, “Pitting action due to bubble formation in the Cooling fluid of a piston liner,” Int. J. Mech. Eng., vol. 1, no. 6, pp. 5–10, 2014, doi: 10.14445/23488360/ijme-v1i6p103.

S. A. E. International and S. A. E. Transactions, “Author ( s ): Lillian M Gilbreth Source?: SAE Transactions , Vol . 20 , PART II ( 1925 ), pp . 735-760 Published by?: SAE International Stable URL?: https://www.jstor.org/stable/44729815,” vol. 20, no. 1925, pp. 735–760, 2018.

A. K. Hossain, D. I. Smith, and P. A. Davies, “Effects of engine cooling water temperature on performance and emission characteristics of a compression ignition engine operated with biofuel blend,” J. Sustain. Dev. Energy, Water Environ. Syst., vol. 5, no. 1, pp. 46–57, 2017, doi: 10.13044/j.sdewes.d5.0132.

S. Muthukumarasamy, R. Dinesh, and K. D. Kumar, “Analysing the Causes of Overheating of Heavy Duty Truck Engines and Heat Flux of Radiator Using Pareto Principle Ansys Software,” vol. 118, no. 20, pp. 4955–4963, 2018.

B. N. Goel, “Case Study?: Failure Analysis of Diesel Engine Cylinder Liners.”

S. Bako, T. Usman, I. Bori, and A. Nasir, “Simulation of a Wet Cylinder Liner,” Int. J. Mech. Eng., vol. 6, no. 4, pp. 12–17, 2019, doi: 10.14445/23488360/ijme-v6i4p103.

Cummins, “Cavitation Corrosion / Erosion Coolant Testing Kit CC2602M or CC2602AM,” p. 2.

S. W. Beni Kurniawan Saputra, M Ginting, “Analisa Pengaruh Penggantian Material Tube Terhadap Kecepatan , Suhu Dan Tekanan Pada Lube Oil Cooler Untuk Pendingin Compressor 103 Di Pt Pusri,” J. Austenit, vol. 8, pp. 33–35, 2016.

D. Belloli, S. M. Savaresi, A. Cologni, F. Previdi, and D. Cazzola, “Modeling and control of an Internal Bubble Cooling system,” 2012 8th Int. Symp. Mechatronics its Appl. ISMA 2012, no. May 2016, 2012, doi: 10.1109/ISMA.2012.6215168.

T. Dow and C. Company, “AMBITROL Inhibited Glycol-based Coolants.”

V. Enontiemonria and O. Nathaniel, “Comparison of the cooling effects of a locally formulated car radiator coolant with water and a commercial coolant,” Int. J. Eng. Sci., vol. 2, no. 1, pp. 254–262, 2013.

M. A. Hosien and S. M. Selim, “Cavitation Erosion Damage in Diesel Engines Wet Cylinder Liners,” ERJ. Eng. Res. J., vol. 40, no. 1, pp. 31–36, 2017, doi: 10.21608/erjm.2017.66330.

S. Jafari et al., “A review of evaporative cooling system concepts for engine thermal management in motor vehicles,” Proc. Inst. Mech. Eng. Part D J. Automob. Eng., vol. 231, no. 8, pp. 1126–1143, 2017, doi: 10.1177/0954407016674606.

A. M. Fsadni and Y. Ge, “Micro bubble formation and bubble dissolution in domestic wet central heating systems,” EPJ Web Conf., vol. 25, 2012, doi: 10.1051/epjconf/20122501016.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Wilarso Wilarso, Firmansyah Azharul, Che Wan Mohd Noor, Dan Mugisidi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.